As more and more businesses aim to be a “one-stop shop,” it’s a no-brainer that wide-format printers would start adding promotional products to their list of services.

You know a good combination when you see one. There are the classics, like peanut butter and jelly or pineapple on pizza (if you disagree, that’s a you problem). All this is to say — increasingly, we’re seeing an intersection between wide-format printing and the promotional products industry.

And it’s a combination that’s right up there with bacon and eggs.

Wide-format presents opportunities not only for things like promotional goods, but also for branding opportunities like wall graphics and signage. Imagine being able to offer a customer a bundle of goodie bags in an event booth backdropped with pop-up displays or even retractable banners.

In fact, Angelique Racicot, wide-format manager for Premier Press in Portland, Oregon, says the most popular types of promotional items that use wide-format printing are typically banners, posters, vehicle wraps, window graphics, wall murals, floor graphics, trade show displays, canvas prints, and decals.

“If you want to create high-impact, visually appealing displays and signage quickly and efficiently, then utilizing wide-format is crucial,” Racicot says.

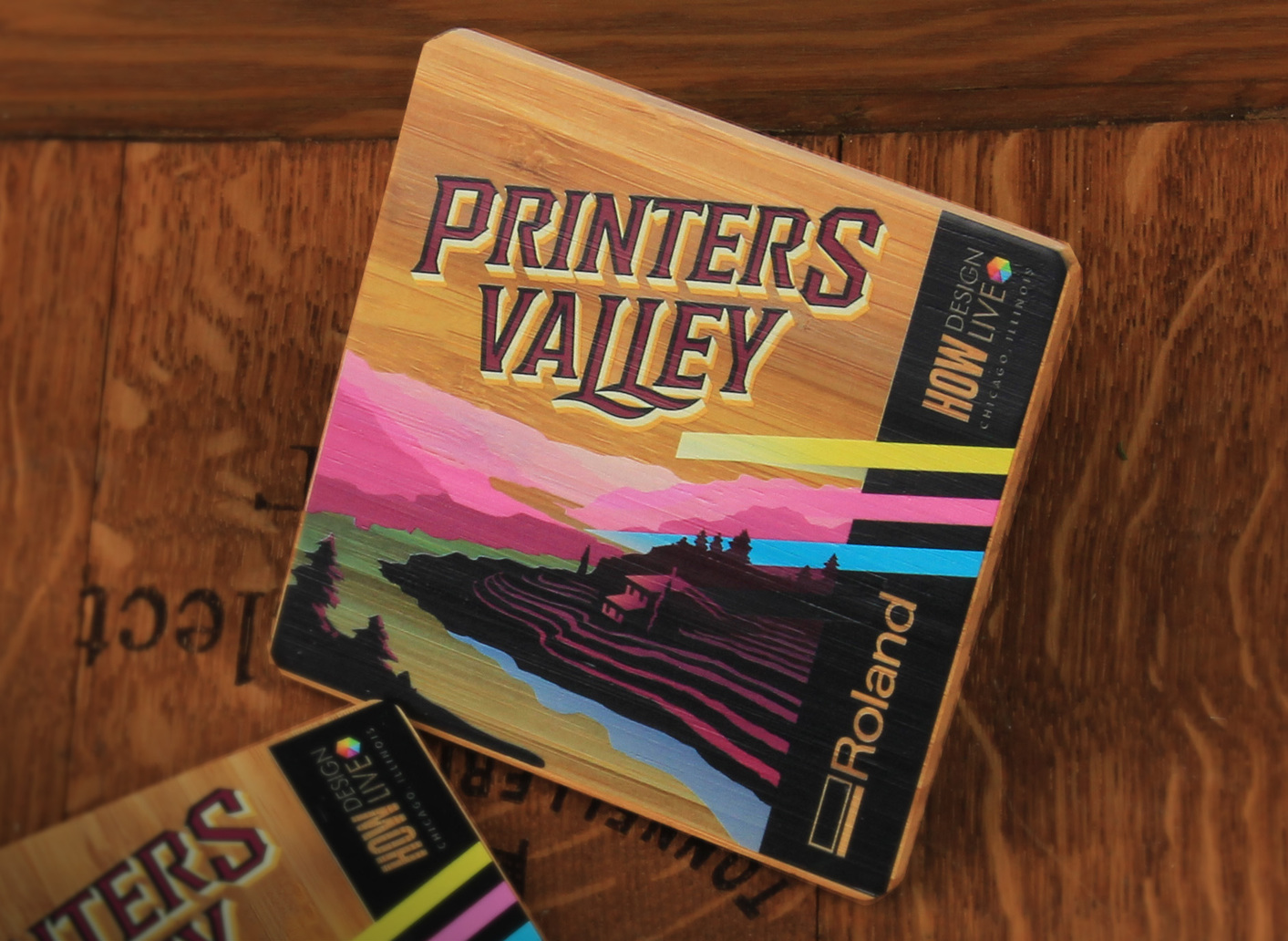

Similarly, Jay Roberts, UV printer product manager for Roland DGA, Irvine, California, says that wide-format printing has revolutionized trade shows and events.

“The ability to print quickly and consistently onto a vast array of materials, all while maintaining high-quality and vibrant colors, is a game changer,” Roberts says. “This versatility allows for seamless brand consistency across all elements, from large attention-grabbing banners and graphics to promotional items handed out at the booth. Everything can visually reinforce your brand identity and create a cohesive and impactful experience for attendees.”

UV Printing and Glossy Inks Are Paving the Way

Roberts says that wide-format UV printing has really helped open the door into the promo space outside of events or signage.

“UV printing has undeniably been a game changer for the promotional product industry,” he says. “This technology has given users the ability to direct-print quickly and easily on a wider variety of materials — practically anything, including plastic, metal, and wood — opening the door to a whole new world of possibilities.”

In addition to UV printing, Roberts says that different inks are also significantly impacting the promotional product industry.

“White ink allows for vibrant color printing on even darker surfaces, eliminating the need for a pre-coated white base, greatly increasing the product options,” Roberts says. “Gloss ink, on the other hand, adds a layer of shine that enhances visual impact, intensifies colors, and creates a more professional and luxurious feel. The combination of these inks allows for eye-catching appeal and increased durability, making them ideal for creating promotional products that grab attention and leaving a lasting brand impression.”

Cutting Down on Costs and Turnaround Times

Essentially, wide-format printing cuts out the middleman. Roberts says that because direct printing allows you to print directly on an object, it eliminates other steps that can elongate the process.

For a distributor or decorator looking to become that all-important one-stop shop for customers, eliminating touch points is crucial. Any opportunity to shave time off of the process will be appreciated by the end-buyer, many of whom require quick turnarounds or even rush jobs in a very impatient world.

“Direct printing is typically more cost-effective, as you’re printing directly onto the product, eliminating the need to create and apply separate stickers like you would do with traditional eco-solvent printing,” Roberts says. “Both methods achieve a similar end-result, but printing directly on an object with a high-quality UV printer, such as a Roland DG VersaOBJECT MO-240 benchtop flatbed printer or CO-i Series large-format UV flatbed, delivers cleaner, more professional, longer-lasting graphic results, with no bulky stickers involved.”

Racicot also sees the financial benefits for decorators, printers, and promotional products distributors investing in wide-format print technology, saying that wide-format printing is more cost-effective for short runs and custom jobs with faster turnaround times.

Roberts mentions that faster turnaround times are a result of wide-format printing eliminating the need for lengthy setup times. As customers get used to this, they’ll expect short turnarounds as the rule, rather than the exception.

“With wide-format printing, there’s no need for plates to be created or screens to be prepped,” Roberts says. “Once your design file is finalized, it’s simply a matter of sending it to the RIP software and hitting ‘print.’ This translates to immediate production and significantly faster turnaround times compared to other printing processes, boosting overall productivity and profitability.”

Printing tip: For those who might be considering adding print, and are therefore not up to date on all of the nomenclature, “RIP” stands for “raster imaging processor.” RIP software converts vector images into raster images made up of individual pixels, which are therefore able to be printed in high quality and high detail.

RIP is crucial for factors like color consistency and allows for simple editing processes like resizing and rotating images.

Practice Makes Perfect

Roberts warns that the two biggest challenges posed when it comes to printing promotional products are adhesion and durability, so he suggests taking a test-drive before anything else. Otherwise, you might end up redoing work and adding even more time to the in-hands date for your customer.

“To ensure success, we always recommend test-printing a sample before placing a large order,” he says. “Such testing will confirm good adhesion, high-quality print results, and cost-effectiveness for your chosen material.”

Racicot explains that some of the challenges she sees include color consistency, media handling, and print durability.

Part of operating print machinery, though, is regular maintenance and knowing what the machinery does best. It’s like owning a car: You need to change the oil every so often, and make sure you know what kind of fuel to put in the car.

“As for some solutions to these problems though, I’d suggest involving regular calibration, using high-quality materials, and also using protective coatings,” Racicot says.

With a reasonable understanding of how wide-format works, and how to keep everything humming along, wide-format printing can complement both your print or promotional products operation by allowing you to appeal to whole new sets of customers, or expanding your business with existing ones.